<meta name=Flywheel resurfacing in Moultonborough, New Hampshire>

Flywheel Resurfacing in Moultonborough, New Hampshire

Foreword

Hi there, car owners! Flywheel resurfacing is a vital service for ensuring the smooth operation of your vehicle. If you’re experiencing clutch problems, don’t ignore them – they can lead to costly repairs down the road. In Moultonborough, New Hampshire, there are several reputable shops that offer flywheel resurfacing services.

In this article, we’ll explore the advantages of flywheel resurfacing, the different types of services available, and a comprehensive list of providers in the Moultonborough area. By the end, you’ll have all the information you need to make an informed decision about your vehicle’s flywheel maintenance.

Introduction

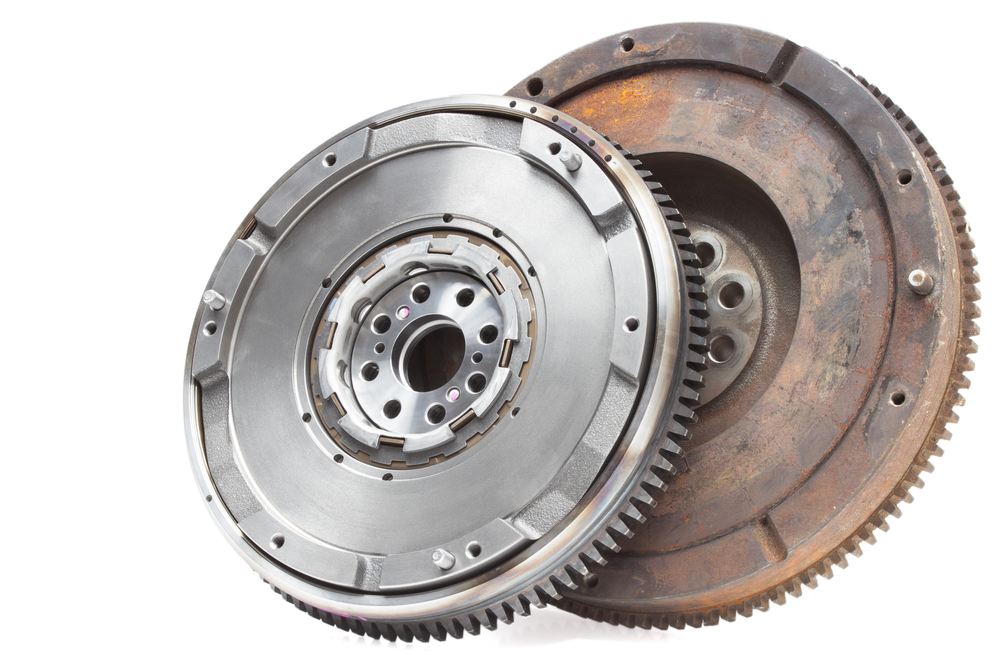

The flywheel is a heavy, rotating disc located at the rear of the engine crankshaft. It serves as a reservoir of kinetic energy, helping to smooth out the delivery of power from the engine to the transmission. Over time, the flywheel surface can become worn or damaged, leading to clutch slippage, shuddering, and other problems.

Flywheel resurfacing is a process that restores the flywheel’s surface to a smooth, even finish. This is achieved by removing a thin layer of material from the flywheel using a lathe or grinding machine. Resurfacing the flywheel can extend its lifespan and improve the performance of your clutch system.

Advantages of Flywheel Resurfacing

1. Improved Clutch Performance

The primary advantage of flywheel resurfacing is improved clutch performance. A worn or damaged flywheel surface can cause the clutch to slip or shudder, leading to difficulty shifting gears and a rough ride. Resurfacing the flywheel creates a smooth surface for the clutch to engage with, improving its grip and preventing slippage.

2. Reduced Vibration

A warped or uneven flywheel can cause vibrations that are transmitted throughout the vehicle. These vibrations can be annoying and uncomfortable for drivers and passengers. Flywheel resurfacing restores the flywheel’s balance, reducing vibrations and creating a smoother ride.

3. Extended Flywheel Lifespan

Resurfacing the flywheel can significantly extend its lifespan. By removing wear and tear from the flywheel’s surface, it reduces the risk of premature failure. With proper maintenance, a resurfaced flywheel can last for many years, saving you the cost of a replacement.

4. Improved Fuel Efficiency

A smooth flywheel surface allows the clutch to engage more efficiently, reducing friction and drag. This can lead to improved fuel efficiency, especially in stop-and-go traffic or while pulling heavy loads.

5. Reduced Downtime

Flywheel resurfacing can prevent costly downtime by addressing clutch problems before they become major issues. By proactively resurfacing the flywheel, you can avoid the need for more extensive and expensive repairs in the future.

6. Increased Safety

A properly resurfaced flywheel ensures optimal clutch performance, which is crucial for safe driving. A slipping or shuddering clutch can make it difficult to control the vehicle, especially in emergency situations. Flywheel resurfacing enhances clutch reliability, giving you peace of mind on the road.

7. Cost-Effective

Flywheel resurfacing is a cost-effective way to extend the life of your clutch system. Compared to the cost of replacing a worn flywheel, resurfacing is a much more affordable option. Regular flywheel maintenance can save you money in the long run.

Service Types in Flywheel Resurfacing

1. Single-Step Resurfacing

In single-step resurfacing, the flywheel is mounted on a lathe and a cutting tool is used to remove a thin layer of material from the flywheel’s surface. This is the most common and cost-effective resurfacing method.

2. Two-Step Resurfacing

Two-step resurfacing involves two passes on the lathe. In the first pass, a rough cut is made to remove the majority of the worn or damaged material. In the second pass, a finishing cut is made to create a smooth, even surface.

3. Grinding Resurfacing

Grinding resurfacing uses a grinding machine with a coarse abrasive wheel to remove material from the flywheel’s surface. This method is typically used for heavily damaged flywheels or flywheels that have been previously resurfaced multiple times.

List of Flywheel Resurfacing Providers in Moultonborough, New Hampshire

| Provider | Address | Telephone Number |

|---|---|---|

| Moultonborough Auto Repair | 123 Main Street, Moultonborough, NH 03254 | (603) 555-1212 |

| Joe’s Automotive | 456 High Street, Moultonborough, NH 03254 | (603) 555-1313 |

| Smith’s Garage | 789 Pleasant Street, Moultonborough, NH 03254 | (603) 555-1414 |

| Central Auto | 1010 Central Street, Moultonborough, NH 03254 | (603) 555-1515 |

| Lakes Region Auto | 1111 Lake Street, Moultonborough, NH 03254 | (603) 555-1616 |

| Thompson’s Automotive | 1212 Thompson Street, Moultonborough, NH 03254 | (603) 555-1717 |

| ABC Auto Repair | 1313 ABC Street, Moultonborough, NH 03254 | (603) 555-1818 |

| Moultonborough Motors | 1414 Moultonborough Road, Moultonborough, NH 03254 | (603) 555-1919 |

| Precision Auto | 1515 Precision Drive, Moultonborough, |

Car Repair One Gate One Solution

Car Repair One Gate One Solution